Lubricating pinion for chain lubrication

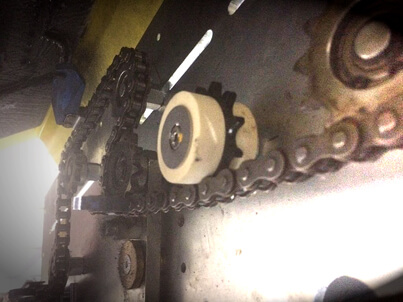

Constant chain care with chain lubrication sprockets

A roller chain should always be well lubricated where friction occurs as a result of chain movement. This is on the link plates, between the chain pins and sleeves, as well as between the chain sleeves and the roller.

This is exactly where the oil gets to relubricate the grease pads with chain lubrication sprockets.

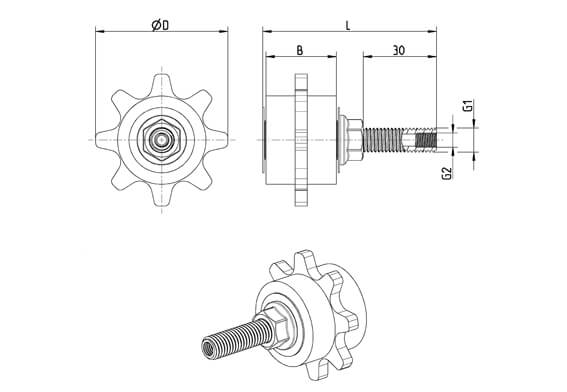

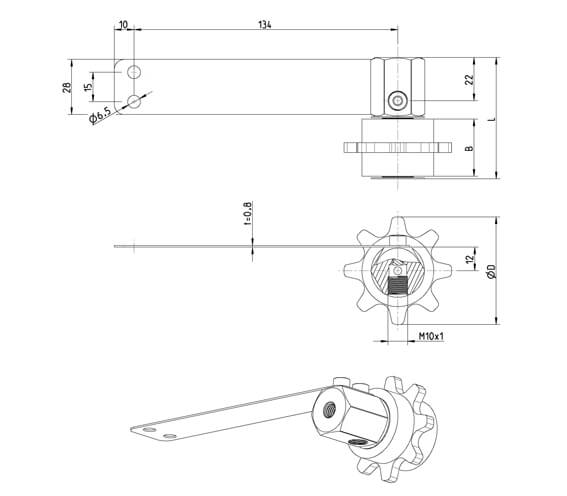

How it Works: See on example of lubricating pinions for a simplex chain

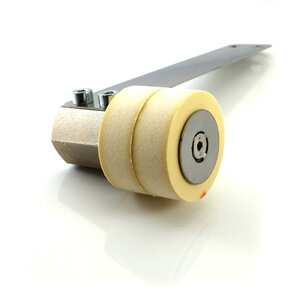

A plastic pinion made of highly wear-resistant plastic runs freely with the chain.

Two open-pore PU foam rings firmly attached to the plastic pinion are thus moved without slippage and at a precisely defined distance from the chain so that only contact between the chain link and PU foam takes place in the area of the chain links.

This contact and the minimal contraction of the PU foam rings allows the lubricating oil supplied through the hollow axle to reach between the link plates exactly where it is needed.

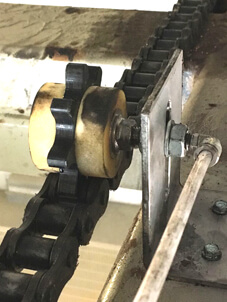

This means that a drive chain or timing chain can be lubricated and maintained most effectively with the least amount of lubricant, without polluting the environment with excess chain oil, which would not be possible with lubricating brushes.

The avoidance of any friction between PU foam cylinder and chain, as well as the always equal, minimal contraction of the high-quality PU material guarantee a maximum service life of this chain lubrication solution.

This is exactly where the oil gets to relubricate the grease pads with chain lubrication sprockets.

How it Works: See on example of lubricating pinions for a simplex chain

A plastic pinion made of highly wear-resistant plastic runs freely with the chain.

Two open-pore PU foam rings firmly attached to the plastic pinion are thus moved without slippage and at a precisely defined distance from the chain so that only contact between the chain link and PU foam takes place in the area of the chain links.

This contact and the minimal contraction of the PU foam rings allows the lubricating oil supplied through the hollow axle to reach between the link plates exactly where it is needed.

This means that a drive chain or timing chain can be lubricated and maintained most effectively with the least amount of lubricant, without polluting the environment with excess chain oil, which would not be possible with lubricating brushes.

The avoidance of any friction between PU foam cylinder and chain, as well as the always equal, minimal contraction of the high-quality PU material guarantee a maximum service life of this chain lubrication solution.

| Chain-Type | Chain-Dim. | G1 | G2 | Order-No. |

|---|---|---|---|---|

| 08 B-1 | 1/2" x 5/16" | M10 | M6 | 012 06 08B1 A |

| 10 B-1 | 5/8" x 3/8" | M10 | M6 | 012 06 10B1 A |

| 12 B-1 | 3/4" x 7/16" | M10 | M6 | 012 06 12B1 A |

| 16 B-1 | 1" x 17,02 | M10 | M6 | 012 06 16B1 A |

| 20 B-1 | 1 1/4" x 3/4" | M16 | M10x1 | 012 06 20B1 A |

| 24 B-1 | 1 1/2" x 1" | M16 | M10x1 | 012 06 24B1 A |

| 32 B-1 | 2" x 1 1/4" | M16 | M10x1 | 012 06 32B1 A |

| Chain-Type | Chain-Dim. | G1 | G2 | Order-No. |

|---|---|---|---|---|

| 08 B-2 | 1/2" x 5/16" | M10 | M6 | 012 06 08B2 A |

| 10 B-2 | 5/8" x 3/8" | M10 | M6 | 012 06 10B2 A |

| 12 B-2 | 3/4" x 7/16" | M10 | M6 | 012 06 12B2 A |

| 16 B-2 | 1" x 17,02" | M16 | M10x1 | 012 06 16B2 A |

| 20 B-2 | 1 1/4" x 3/4" | M16 | M10x1 | 012 06 20B2 A |

| 24 B-2 | 1 1/2" x 1" | M16 | M10x1 | 012 06 24B2 A |

| 32 B-2 | 2" x 1 1/4" | M16 | M10x1 | 012 06 32B2 A |

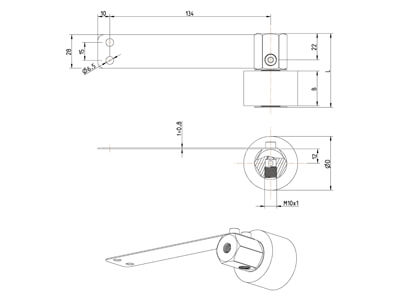

Lubricating pin with angled axle and spring plate for the chain lubrication

Constant chain care with chain sprockets

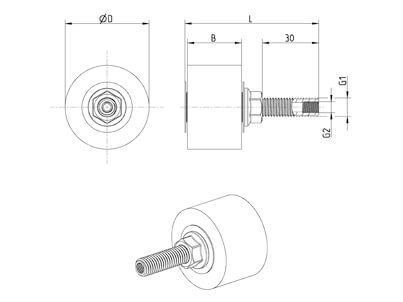

Lubricating rollers for universal lubrication tasks

For constant lubrication of surfaces or specially shaped contours

Lubricating rollers in various widths and diameters are particularly suitable for the even application of very small amounts of lubricant on surfaces.

In combination with the proven spring plates, the ideal contact pressure is guaranteed to achieve the best lubrication results.

In combination with the proven spring plates, the ideal contact pressure is guaranteed to achieve the best lubrication results.