SputtMiK DUSTPROOF

The solution if the "standard" is not enough. The robust sheet metal housing of the SputtMiK DUSTPROOF variants not only protects the contents from chips, dust and spray water, but also allows variable accommodation of various additional functions of the SputtMiK lubricators.Possible Features

Timer

Fully automatic time control for freely adjustable lubrication intervals

Sensor

Sensor controlled spraying

Float Switch

Level monitoring with signal at the device and / or at the system with a low level

Automatic Filling

Central lubrication system with automatic filling from large containers such as canisters or drums.

Two Reservoir

Spray device with two storage containers, e.g. for cleaning intervals

Function Monitoring

Function monitoring for maximum process reliability

Application Example I:

SputtMiK DUSTPROOF 3P2L

Central Lubrication System with 5 Dosing-Pumps

- Pump block with three dosing pumps (left side) for oil supply via lubrication brush

- Pump block with two dosing pumps (right side) for oil supply via two-fluid spray nozzles

- 3L oil reservoir with "bubble pipe" for mixing the lubricant (lubricating oil with PTFE additives)

- Integrated compressed air supply with pressure reducer and control valves

- Digital frequency generator DigiTimer for clocking the dosing pumps

Three pump elements (left block) for precise lubricant dosing.

The lubricant is passed to the lubrication point (a transport chain) via a simple hose and applied with a lubricant brush.

The two right pump elements are equipped with all screw connections for the STW coaxial hose system. The lubricant dosed there is applied by means of two-fluid nozzles.

A frequency generator (STW-DigiTimer) controls the clock frequency of all installed dosing pumps at the same time, but the flow rate has to be set individually and precisely for each lubrication point and to the 1/1000 part of a liter.

(For comparison, a drop of 50/1000 liters is defined in pharmacology).

Advantages:

- Highly precise dosage

- Individually adjustable for each lubrication point

- One central Lubrication-System

- One central Reservoir

- Easy to control

A further special feature is the oil reservoir with bublle-pipe for mixing the lubricating media, which tend to disintegrate again. A simple solution but only suitable for particularly low-viscosity liquids. Air dissolved in the lubricant can affect metering accuracy. Better solution: TopTankTornado, the oil reservoir with agitator.

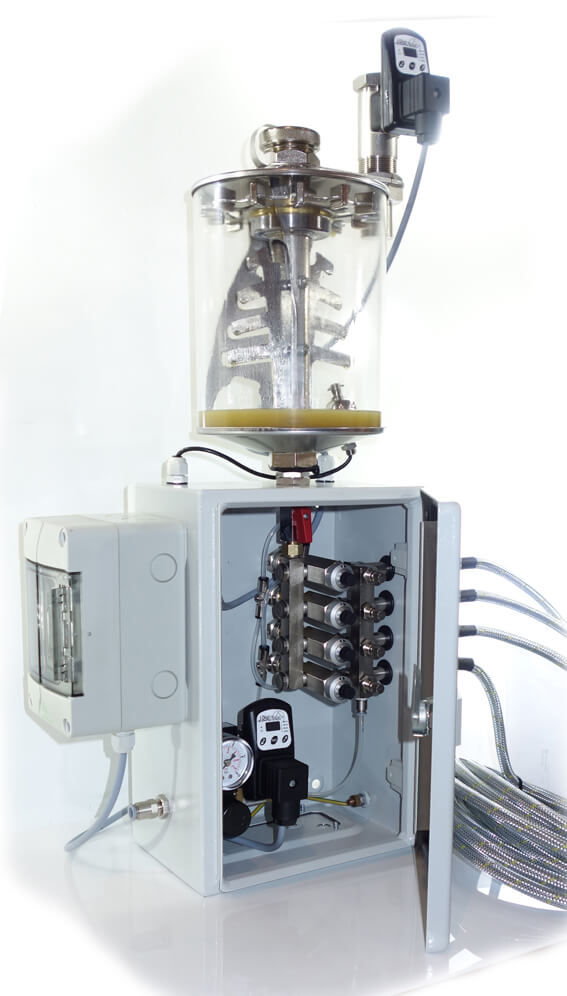

Application Example II:

SputtMiK DUSTPROOF 4P 3R

Central Lubrication System with 4 Dosing-Pumps

- Pump block with 4 dosing pumps for oil supply via two-fluid spray nozzles

- Time control to autonomous chain lubrication at regular intervals

- 3L oil reservoir with agitator and float switch

- Automatic shut-off at low oil level

- Integrated compressed air supply with pressure reducer and control valves

- Digital frequency generator DigiTimer for clocking the dosing pumps during the operating time

Four flat-jet nozzles are used to lubricate two extremely fast moving and highly loaded triplex chains with support lugs.

The system switches on every 20 minutes for 30 seconds to apply evenly the lubricant at 2 Hz pump-stroke-frequency.

The agitator of the oil reservoir keeps the special lubricant with its highly effective additives homogeneous. It mixes the container independently of the lubrication times every 30 min. for 6 min.

The integrated level check signals the min. level of the oil tank and stops the lubricator automatically.

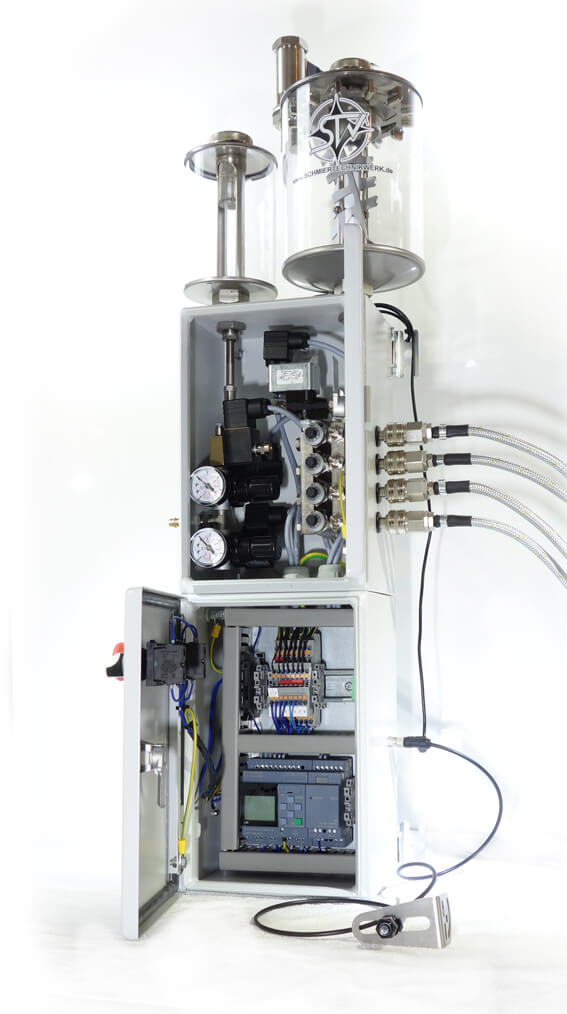

Application Example III:

SputtMiK DUSTPROOF 4P 3R+1 RL

PLC controled 4-pump central lubrication system

- Pump block with 4 dosing pumps for oil supply via two-fluid spray nozzles

- Programmable controller with individual program

- 3L oil reservoir with agitator and float switch

- Detection and reporting of the minimum oil level in the main tank

- Second reservoir for cleaning medium

- Automatic medium change according to programming for cleaning mode

- Integrated compressed air supply with pressure reducer and control valves

- Second compressed air unit for high-pressure air cleaning jet via the spray nozzles

- Automatic activation of the air-jet cleaning according to programming

- Sensor-controlled spray pulse triggering for point accuracy Lubrication of chain links

- Easy assembly by connecting / disconnecting all incoming and outgoing lines (compressed air supply, power supply, coaxial spray oil lines and sensor cable)

Fully autonomous and freely programmable spray lubrication system. Specially designed for the permanent and continuous care of the chain, this minimum quantity lubrication system enables the fully automatic execution of cleaning cycles. In accordance with the programmed parameters, the device automatically switches to a second container with cleaning liquid to spray it in the desired quantity. After the cleaning agent has been applied, a compressed air cleaning interval follows over the standard nozzles in order to remove the adhering dirt with a multiple of the "spray air pressure". When this cleaning interval is complete, the system switches back to the standard lubrication mode.