Dose Oiler or Oil Dispenser

Universal Lubricators for the precise dispensing of lubricant media

Pumptype: DPV-25 / 100

Pneumatic Piston Pump

Doseing volume: Variable

Doseing volume per Stroke:

0 - 100 mm^3

Pressure max:

80 bar

Multipoint Lubrication: Yes

One Pump per Lubrication-Point

Pneumatic Piston Pump

Doseing volume: Variable

Doseing volume per Stroke:

0 - 100 mm^3

Pressure max:

80 bar

Multipoint Lubrication: Yes

One Pump per Lubrication-Point

Pumptype: DEK-15 / 30

Electric Piston Pump

Doseing volume: Constant

Doseing volume per Stroke:

15 or 30 mm^3

Pressure max:

5 to 60 bar depending on Type

Multipoint Lubrication: Yes

One Piston per Lubrication-Point

Electric Piston Pump

Doseing volume: Constant

Doseing volume per Stroke:

15 or 30 mm^3

Pressure max:

5 to 60 bar depending on Type

Multipoint Lubrication: Yes

One Piston per Lubrication-Point

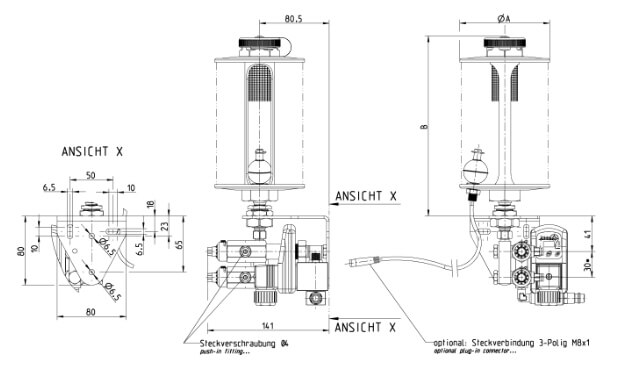

Type DPV - 25 / 100

Pneumatic Dose Oiler or Oil Dispenser with variable adjustable Displacement

Traditional lubricators quickly reach their limits when lubricating chains, conveyor belts, slide rails and the like, since in modern plants, over-oiling and the associated contamination of the environment with lubricants can no longer be accepted.

With a gravity drip feed oiler which delivers significantly more medium when the container is full than when the filling level is low, exact dosage - even in the drop area - can not be achieved.

Microdosing pumps originally developed for the minimum quantity cooling lubrication in the machining industry are the almost perfect alternative.

The infinitely adjustable conveying capacity of 0-25 microliter with the smal Pump or 0-100 microliter with the larger one and the robust, simple and reliable mechanics make it possible.

The application of the lubricant to, for example, a conveyor chain takes place, as in the case of known oildrippers, via a lubricating brush of the appropriate width or a lubricating pinion.

When laying the connecting hose, nothing has to be taken into account and it can bridge distances of more than 20 m depending on the viscosity of the lubricating oil. The discharge pressure is up to 80 bar.

In combination with the STW-DigiTimer, it is reliably possible to lubricate lubrication points in a number of individual cans in a period of one week, which in sum only form one drop of oil.

With a gravity drip feed oiler which delivers significantly more medium when the container is full than when the filling level is low, exact dosage - even in the drop area - can not be achieved.

Microdosing pumps originally developed for the minimum quantity cooling lubrication in the machining industry are the almost perfect alternative.

The infinitely adjustable conveying capacity of 0-25 microliter with the smal Pump or 0-100 microliter with the larger one and the robust, simple and reliable mechanics make it possible.

The application of the lubricant to, for example, a conveyor chain takes place, as in the case of known oildrippers, via a lubricating brush of the appropriate width or a lubricating pinion.

When laying the connecting hose, nothing has to be taken into account and it can bridge distances of more than 20 m depending on the viscosity of the lubricating oil. The discharge pressure is up to 80 bar.

In combination with the STW-DigiTimer, it is reliably possible to lubricate lubrication points in a number of individual cans in a period of one week, which in sum only form one drop of oil.

Choose:

The size of the storage container (one, two or three liters)

Filling level monitoring (yes / no)

Number of dosing pumps

Supply voltage (24 - 48 V DC or 110 - 230 V AC)

DigiTimer (yes / no)

... and ask for an offer ....

Order-Number:

| Number of Dosing Pumps | Oil Tank size | Valve voltage | |

|---|---|---|---|

| 08 | XX | XX | XXX |

| 01 = one Dosing-Pump 02 = two Dosing-Pumps 03 = three Dosing-Pumps 04 = four Dosing-Pumps |

01 = 1L 02 = 2L 03 = 3L |

024 = 24 V DC 048 = 48 V DC 110 = 110 V AC 230 = 230 V AC |

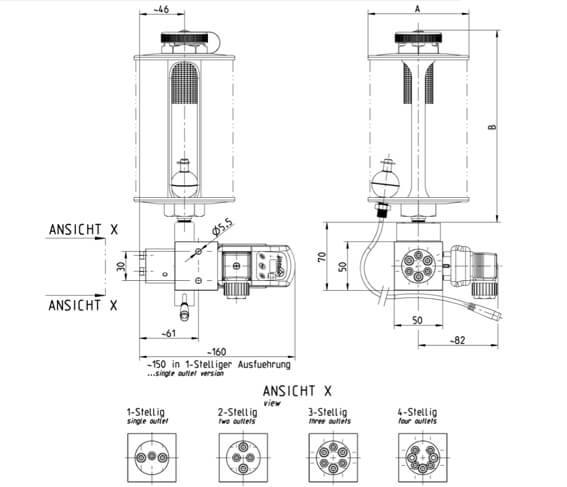

Type DEK-15 / 30

Electric Dose Oiler or Oil Dispenser with constant Displacement

The DEK-15/30 dosing oiler is a purely electrically operated lubrication unit for small-quantity lubrication, which can be equipped with one to four pistons and can provide this number of lubrication points.

Perfectly suited for combination with STW lubricating brushes, which distribute the dosed lubricant oil evenly. The DEK-15 does not require compressed air and is thus easy to integrate into existing systems.

The tried and tested and robust oil containers in the sizes 1,2 or 3 liters can be equipped with a float switch for filling level monitoring.

In combination with the optionally available time control "STW-DigiTimer", the amount of lubricant to be dispensed can be set uncomplicated over the number of piston strokes per time.

Perfectly suited for combination with STW lubricating brushes, which distribute the dosed lubricant oil evenly. The DEK-15 does not require compressed air and is thus easy to integrate into existing systems.

The tried and tested and robust oil containers in the sizes 1,2 or 3 liters can be equipped with a float switch for filling level monitoring.

In combination with the optionally available time control "STW-DigiTimer", the amount of lubricant to be dispensed can be set uncomplicated over the number of piston strokes per time.

Choose:

The size of the storage container (one, two or three liters)

Filling level monitoring (yes / no)

Number of dosing pumps

Supply voltage (24 - 48 V DC or 110 - 230 V AC)

DigiTimer (yes / no)

... and ask for an offer ....

Order-Number:

| Number of Dosing-Pistons | Oil Tank size | Voltage | |

|---|---|---|---|

| 09 | XX | XX | XXX |

| 01 = one Dosing-Piston 02 = two Dosing-Pistons 03 = three Dosing-Pistons 04 = four Dosing-Pistons |

01 = 1L 02 = 2L 03 = 3L |

024 = 24 V DC 230 = 230 V AC |

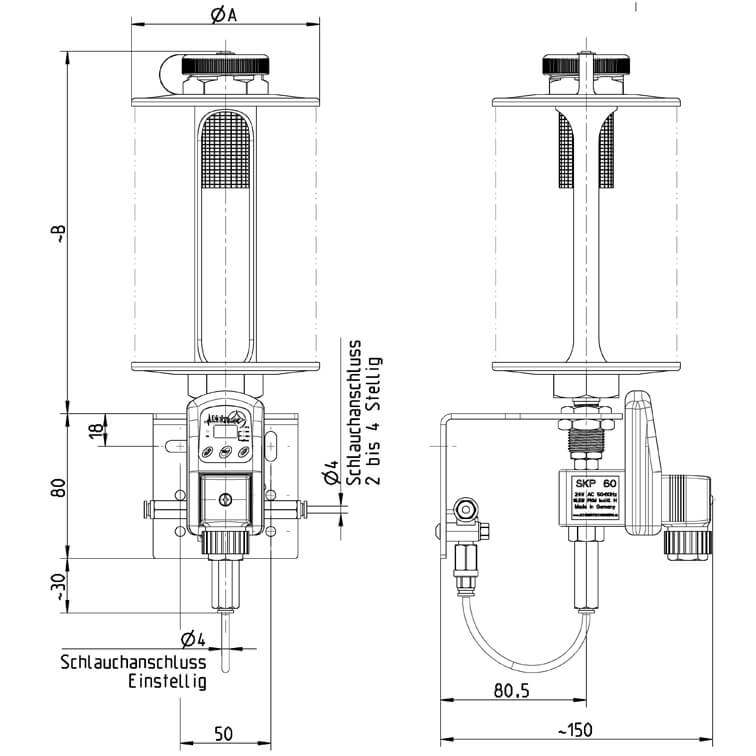

ecoOiler eO-60

Chain lubrication unit for up to four lubricating brushes, roller brushes or lubricating brooms.

The ecoOiler eO-60 is the simplest and most cost-effective solution for supplying all types of drive chains or conveyor chains with lubricating oil.

The compact dosing pump with 60 mm^3 displacement per stroke can supply up to four lubrication points at a maximum delivery pressure of 6 bar.

For this purpose, the delivery volume can be divided in up to four lubricant lines in a distributor unit. Ideal for combination with lubricating brushes, roler brushes or lubrication pinions.

The tried and tested and robust oil containers in the sizes 1,2 or 3 liters can be equipped with a float switch for filling level monitoring.

In combination with the optionally available time control "STW-DigiTimer", the amount of lubricant to be dispensed can be set uncomplicated over the number of piston strokes per time.

The compact dosing pump with 60 mm^3 displacement per stroke can supply up to four lubrication points at a maximum delivery pressure of 6 bar.

For this purpose, the delivery volume can be divided in up to four lubricant lines in a distributor unit. Ideal for combination with lubricating brushes, roler brushes or lubrication pinions.

The tried and tested and robust oil containers in the sizes 1,2 or 3 liters can be equipped with a float switch for filling level monitoring.

In combination with the optionally available time control "STW-DigiTimer", the amount of lubricant to be dispensed can be set uncomplicated over the number of piston strokes per time.

Choose:

The size of the storage container (one, two or three liters)

Filling level monitoring (yes / no)

Number of dosing pumps

Supply voltage (24 AC or 230 V AC)

DigiTimer (yes / no)

... and ask for an offer ....

Order-Number:

| Number of Outlets | Oil Tank size | Voltage | |

|---|---|---|---|

| 07 | XX | XX | XXX |

| 01 = one Outlet 02 = two Outlets 03 = three Outlets 04 = four Outlets |

01 = 1L 02 = 2L 03 = 3L |

024 = 24 V AC 230 = 230 V AC |